factory Outlets for OEM Customzied China Factory Hard Alloy Cemented Tungsten Carbide Punch Rod

To become the stage of realizing dreams of our employees! To build a happier, additional united and additional experienced team! To reach a mutual gain of our clients, suppliers, the society and ourselves for factory Outlets for OEM Customzied China Factory Hard Alloy Cemented Tungsten Carbide Punch Rod, At present, corporation name has much more than 4000 kinds of products and gained very good status and big shares on current market domestic and abroad.

To become the stage of realizing dreams of our employees! To build a happier, additional united and additional experienced team! To reach a mutual gain of our clients, suppliers, the society and ourselves for China Tungsten Carbide Rod and Carbide Punch, At Current, our solutions have been exported to more than sixty countries and different regions, such as Southeast Asia, America, Africa, Eastern Europe, Russia, Canada etc. We sincerely hope to establish wide contact with all potential customers both in China and the rest part of the world.

Product description

The cemented carbide rods material produced by our company has the characteristics of stable performance, easy welding, wear resistance and impact resistance. The material is mainly used in cutting tool manufacturing, endmills ,drill, milling cutter. Carbide rods can be used for cutting ,stamping and measuring tools ,

woodworking drill bits, metal milling cutters, and various non-ferrous metal processing fields.

Our company mainly provides h5 ,h6 tolerence grounded carbide rods and carbide rod blanks .

According to customers feedback ,our materials can perfectly replace European carbide brands .we can save our customers a lot of production costs.

Our Best Materials for Carbide Rods

| Our Grade | ISO Grade | Chemical Compostion | Physical Properties | Recommand use for work condition | |||||

| WC% | Co% | Ni% | Other % | Hardness | TRS | Density | |||

| HRA | Mpa | g/cm³ | |||||||

| ZW05F | K05 | 94 | 5 | / | 1 | 94 | 2800 | 14.9 | Super fine grain,excellent wear resistance,apply to reamer,carbon cutter and bamboo wood cutters |

| ZW30F | K30 | 89 | 10 | / | 1 | 92 | 3800 | 14.4 | Subfine grain,apply to make kinds of hole cutting tools ,milling cutters,drill bits,taps and revolving graters etc, also apply to process carbon steel,cold hard cast iron, nonferrous alloy ,kinds of plastic materials,carbon fiber etc,and ideal material for coated tools |

| ZW40F | K40 | 87 | 12 | / | 1 | 92.8 | 4200 | 14.1 | Super fine grain,excellent organizational structure,high hardness and wear-resiatance,Special recommendation to manufacture types of endmills, especially high speed milling tools,Apply to manufacture the cutters for hard-manufacturing types of steel ,stailess steel ,titanium alloy ,die steel (hardness <60HRC) |

Also We can supply

1 Carbide rods blanks

2 Coated Carbide Rods

3 Carbide rods with holes

4 Carbide rods with 30°degree helix holes

5 Carbide rods and carbide tips for gundrills

Technological Process of Production

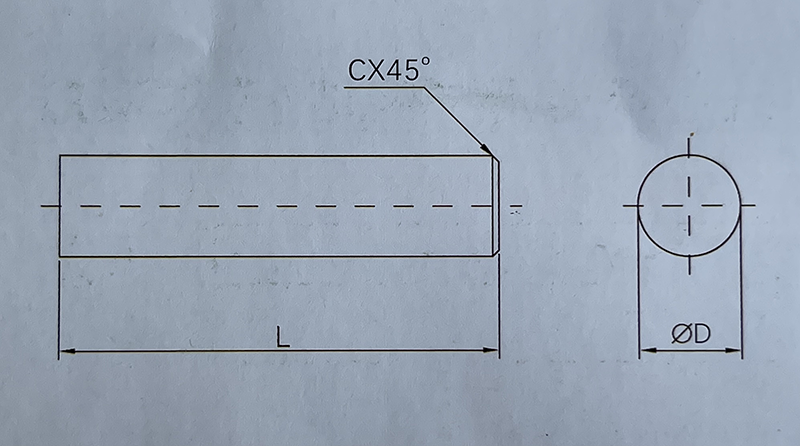

Main Specifications

| Dia (mm) | Length (mm) Tol:0,+1 | Chamfer Tol:±0.1 | angle of chamfer (Tol:±3°) | Dia (mm) | Length (mm) Tol:0,+1 | Chamfer Tol:±0.1 | angle of chamfer (Tol:±3°) |

| 3 | 40 | 0.4 | 45° | 8 | 80 | 0.6 | 45° |

| 3 | 50 | 0.4 | 45° | 8 | 90 | 0.6 | 45° |

| 3 | 70 | 0.4 | 45° | 8 | 100 | 0.6 | 45° |

| 3 | 100 | 0.4 | 45° | 8 | 150 | 0.6 | 45° |

| 3 | 150 | 0.4 | 45° | 10 | 70 | 0.6 | 45° |

| 4 | 40 | 0.4 | 45° | 10 | 75 | 0.6 | 45° |

| 4 | 50 | 0.4 | 45° | 10 | 90 | 0.6 | 45° |

| 4 | 75 | 0.4 | 45° | 10 | 100 | 0.6 | 45° |

| 4 | 100 | 0.4 | 45° | 10 | 125 | 0.6 | 45° |

| 4 | 150 | 0.4 | 45° | 11 | 110 | 0.8 | 45° |

| 5 | 50 | 0.5 | 45° | 12 | 75 | 0.8 | 45° |

| 5 | 55 | 0.5 | 45° | 12 | 90 | 0.8 | 45° |

| 5 | 60 | 0.5 | 45° | 12 | 100 | 0.8 | 45° |

| 5 | 70 | 0.5 | 45° | 12 | 120 | 0.8 | 45° |

| 5 | 80 | 0.5 | 45° | 14 | 75 | 0.8 | 45° |

| 5 | 100 | 0.5 | 45° | 14 | 110 | 0.8 | 45° |

| 5 | 150 | 0.5 | 45° | 14 | 125 | 0.8 | 45° |

| 6 | 50 | 0.5 | 45° | 16 | 100 | 0.8 | 45° |

| 6 | 60 | 0.5 | 45° | 16 | 125 | 0.8 | 45° |

| 6 | 75 | 0.5 | 45° | 18 | 100 | 0.8 | 45° |

| 6 | 100 | 0.5 | 45° | 18 | 150 | 0.8 | 45° |

| 6 | 150 | 0.5 | 45° | 20 | 100 | 1.0 | 45° |

| 7 | 55 | 0.6 | 45° | 20 | 120 | 1.0 | 45° |

| 7 | 60 | 0.6 | 45° | 20 | 150 | 1.0 | 45° |

| 8 | 60 | 0.6 | 45° | 25 | 100 | 1.0 | 45° |

| 8 | 75 | 0.6 | 45° | 25 | 150 | 1.0 | 45° |

FAQs

Q:Can I get free testing samples?

A:Yes, trail order is available after effective communication.

Q:How about the leading time ?

A:We have regular specifications in stock, and can be shipped within three days after confirming the contract.

Q:Can you also supply other accessories for waterjet machine?

Yes, we have waterjet machines suppliers who that have cooperated for many years, we can provide you the other accessories with high-quality, lower-price .

Q:Can your factory provide OEM production?

A:Yes, if your purchase quantity meets the requirements, we can design the packaging for you according to your requirements

Q:Do you guarantee the quality?

A:Yes, we have quality-guaranteed tracking services for the products that have been sold. If you have any questions, please feel free to contact our sales staff. You will get satisfactory after-sales service within 24 hours.

ntroducing the ultimate engineering solution – Carbide Rods: the go-to material for any project that requires consistent performance and durability. Ranging from industrial applications to household hardware, Carbide Rods stand out from the crowd with their incredible strength and long-lasting characteristics.

Produced from high-quality tungsten carbide powder, these rods are manufactured by sintering at high temperatures and pressures, resulting in a uniform grain size and high hardness level. With a melting point of 2,870°C and an outstanding resistance to wear and tear, Carbide Rods are perfect for challenging conditions that demand superior quality and reliability.

Carbide Rods come in a range of sizes and shapes, making them flexible and adaptable to any project needs. They are available in solid or hollow form, with diameters ranging from 2mm to 32mm, and lengths of up to 330mm. They can be machined into various shapes, including round, square, hexagonal, and even triangle.

One of the most significant advantages of Carbide Rods is their high versatility, which enables them to be used in various applications. They are commonly utilized in the manufacturing of cutting tools such as drill bits, end mills, and reamers, in addition to saw blades and cold heading punches, which require resistance to wear and toughness.

Carbide Rods’ excellent thermal and mechanical properties make them ideal for applications that involve high-speed cutting, abrasive materials, and extreme temperatures. These properties allow the rods to withstand heavy stresses without chipping, cracking, or breaking.

In summary, Carbide Rods are perfect for any project that requires consistency, precision, and durability. They are designed to offer superior quality and reliability, regardless of the conditions they are subjected to. They are the ideal material for demanding and challenging applications, where high performance and long service life are essential.

Whether you are an engineer, machinist, DIY enthusiast, or simply looking for a robust material for your household tools, Carbide Rods are the perfect solution. Experience the difference in quality and performance for yourself and take advantage of the improved efficiency and extended service life that Carbide Rods offer.