Factory Cheap Carbide Solid Round Bar, Solid Carbide Rod Price, High Quality Tungsten Carbide Rod

It truly is our responsibility to fulfill your requirements and successfully provide you. Your fulfillment is our best reward. We’re seeking forward in your check out for joint development for Factory Cheap Carbide Solid Round Bar, Solid Carbide Rod Price, High Quality Tungsten Carbide Rod, In addition, we would properly guideline the shoppers about the application techniques to adopt our products and solutions as well as the way to select appropriate materials.

It truly is our responsibility to fulfill your requirements and successfully provide you. Your fulfillment is our best reward. We’re seeking forward in your check out for joint development for China Tungsten Carbide Rods and High Quality Tungsten Carbide Rod, Our company is an international supplier on this kind of merchandise. We present an amazing selection of high-quality products. Our goal is to delight you with our distinctive collection of mindful solutions while providing value and excellent service. Our mission is simple: To offer the best solutions and service to our customers at the lowest prices possible.

Product description

The cemented carbide rods material produced by our company has the characteristics of stable performance, easy welding, wear resistance and impact resistance. The material is mainly used in cutting tool manufacturing, endmills ,drill, milling cutter. Carbide rods can be used for cutting ,stamping and measuring tools ,

woodworking drill bits, metal milling cutters, and various non-ferrous metal processing fields.

Our company mainly provides h5 ,h6 tolerence grounded carbide rods and carbide rod blanks .

According to customers feedback ,our materials can perfectly replace European carbide brands .we can save our customers a lot of production costs.

Our Best Materials for Carbide Rods

| Our Grade | ISO Grade | Chemical Compostion | Physical Properties | Recommand use for work condition | |||||

| WC% | Co% | Ni% | Other % | Hardness | TRS | Density | |||

| HRA | Mpa | g/cm³ | |||||||

| ZW05F | K05 | 94 | 5 | / | 1 | 94 | 2800 | 14.9 | Super fine grain,excellent wear resistance,apply to reamer,carbon cutter and bamboo wood cutters |

| ZW30F | K30 | 89 | 10 | / | 1 | 92 | 3800 | 14.4 | Subfine grain,apply to make kinds of hole cutting tools ,milling cutters,drill bits,taps and revolving graters etc, also apply to process carbon steel,cold hard cast iron, nonferrous alloy ,kinds of plastic materials,carbon fiber etc,and ideal material for coated tools |

| ZW40F | K40 | 87 | 12 | / | 1 | 92.8 | 4200 | 14.1 | Super fine grain,excellent organizational structure,high hardness and wear-resiatance,Special recommendation to manufacture types of endmills, especially high speed milling tools,Apply to manufacture the cutters for hard-manufacturing types of steel ,stailess steel ,titanium alloy ,die steel (hardness <60HRC) |

Also We can supply

1 Carbide rods blanks

2 Coated Carbide Rods

3 Carbide rods with holes

4 Carbide rods with 30°degree helix holes

5 Carbide rods and carbide tips for gundrills

Technological Process of Production

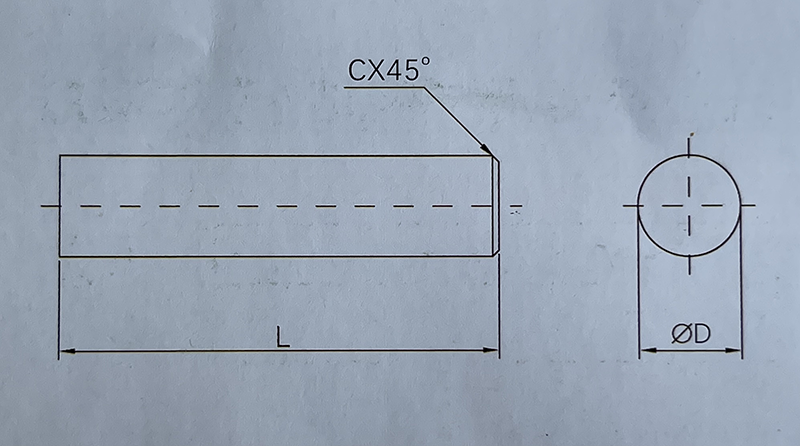

Main Specifications

| Dia (mm) | Length (mm) Tol:0,+1 | Chamfer Tol:±0.1 | angle of chamfer (Tol:±3°) | Dia (mm) | Length (mm) Tol:0,+1 | Chamfer Tol:±0.1 | angle of chamfer (Tol:±3°) |

| 3 | 40 | 0.4 | 45° | 8 | 80 | 0.6 | 45° |

| 3 | 50 | 0.4 | 45° | 8 | 90 | 0.6 | 45° |

| 3 | 70 | 0.4 | 45° | 8 | 100 | 0.6 | 45° |

| 3 | 100 | 0.4 | 45° | 8 | 150 | 0.6 | 45° |

| 3 | 150 | 0.4 | 45° | 10 | 70 | 0.6 | 45° |

| 4 | 40 | 0.4 | 45° | 10 | 75 | 0.6 | 45° |

| 4 | 50 | 0.4 | 45° | 10 | 90 | 0.6 | 45° |

| 4 | 75 | 0.4 | 45° | 10 | 100 | 0.6 | 45° |

| 4 | 100 | 0.4 | 45° | 10 | 125 | 0.6 | 45° |

| 4 | 150 | 0.4 | 45° | 11 | 110 | 0.8 | 45° |

| 5 | 50 | 0.5 | 45° | 12 | 75 | 0.8 | 45° |

| 5 | 55 | 0.5 | 45° | 12 | 90 | 0.8 | 45° |

| 5 | 60 | 0.5 | 45° | 12 | 100 | 0.8 | 45° |

| 5 | 70 | 0.5 | 45° | 12 | 120 | 0.8 | 45° |

| 5 | 80 | 0.5 | 45° | 14 | 75 | 0.8 | 45° |

| 5 | 100 | 0.5 | 45° | 14 | 110 | 0.8 | 45° |

| 5 | 150 | 0.5 | 45° | 14 | 125 | 0.8 | 45° |

| 6 | 50 | 0.5 | 45° | 16 | 100 | 0.8 | 45° |

| 6 | 60 | 0.5 | 45° | 16 | 125 | 0.8 | 45° |

| 6 | 75 | 0.5 | 45° | 18 | 100 | 0.8 | 45° |

| 6 | 100 | 0.5 | 45° | 18 | 150 | 0.8 | 45° |

| 6 | 150 | 0.5 | 45° | 20 | 100 | 1.0 | 45° |

| 7 | 55 | 0.6 | 45° | 20 | 120 | 1.0 | 45° |

| 7 | 60 | 0.6 | 45° | 20 | 150 | 1.0 | 45° |

| 8 | 60 | 0.6 | 45° | 25 | 100 | 1.0 | 45° |

| 8 | 75 | 0.6 | 45° | 25 | 150 | 1.0 | 45° |

FAQs

Q:Can I get free testing samples?

A:Yes, trail order is available after effective communication.

Q:How about the leading time ?

A:We have regular specifications in stock, and can be shipped within three days after confirming the contract.

Q:Can you also supply other accessories for waterjet machine?

Yes, we have waterjet machines suppliers who that have cooperated for many years, we can provide you the other accessories with high-quality, lower-price .

Q:Can your factory provide OEM production?

A:Yes, if your purchase quantity meets the requirements, we can design the packaging for you according to your requirements

Q:Do you guarantee the quality?

A:Yes, we have quality-guaranteed tracking services for the products that have been sold. If you have any questions, please feel free to contact our sales staff. You will get satisfactory after-sales service within 24 hours.

Carbide rods are a highly sought-after industrial component that can be used to create a variety of high-performance cutting tools, such as drill bits, end mills, reamers, and more. These rods are made from a mix of tungsten carbide and cobalt, which gives them their exceptional hardness, wear resistance, and toughness.

Carbide rods are ideal for use in high-temperature, high-stress applications where other materials might fail. They have excellent heat conductivity properties, which makes them ideal for machining hard or abrasive materials like cast iron, titanium, and composites. Carbide rods are also ideal for use in precision machining, thanks to their high dimensional accuracy and stability.

When it comes to selecting carbide rods, there are several things to consider, such as the grade, size, and finish. Carbide rods come in a variety of grades, which are based on the percentage of tungsten carbide used in the mixture. Higher grades will have a higher percentage of tungsten carbide, which makes them more durable and wear-resistant.

Size is also an important consideration when selecting carbide rods. Depending on the application, the rods may need to be larger or smaller, and they may also come in different shapes. Some popular shapes include round, square, and rectangular, and different dimensions relate to different applications.

Finish is another important consideration when selecting carbide rods, as it can impact the quality of the finished product. The finish refers to the surface quality of the rods, and it can be determined by the type of grinding process used. A rougher finish will be less precise, while a finer finish will be more precise and provide better surface quality.

Overall, carbide rods are a versatile and durable material that can be used in a wide range of applications. They are an excellent choice for anyone looking for high-performance cutting tools that can handle demanding manufacturing processes. If you are interested in using carbide rods for your manufacturing processes, be sure to do your research and select the best quality rods for your specific needs.